Blogs

- Home

- Blogs

- Wednesday, Dec 24, 2025

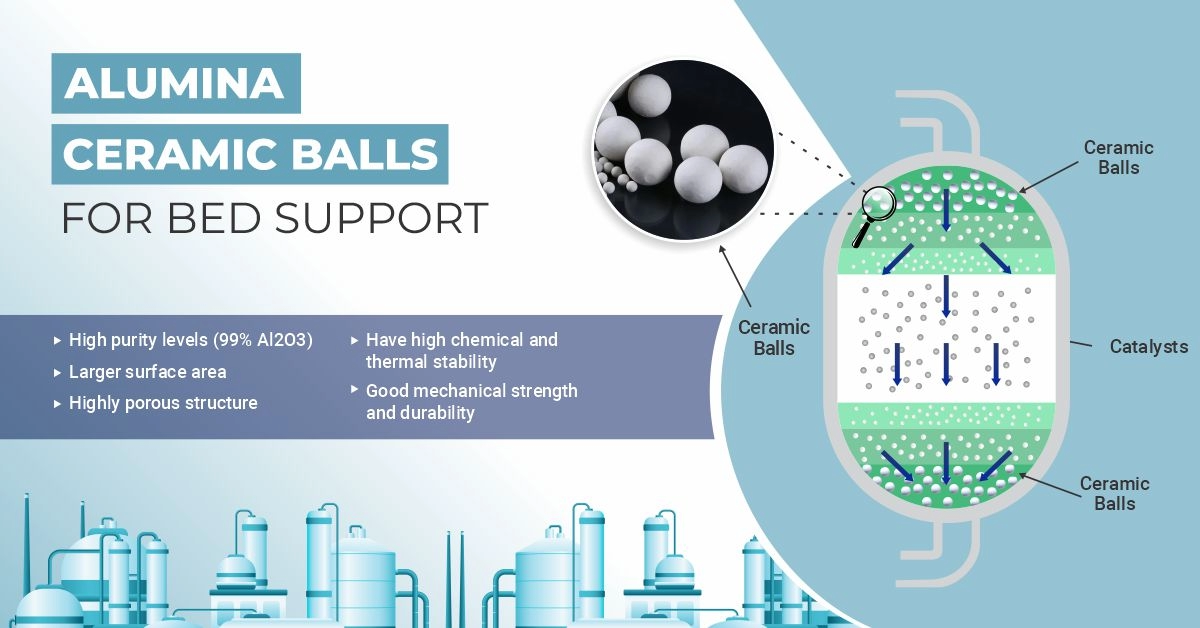

What is The Role of Inert Ceramic Balls in Industrial Filtration?

Read More...

- Thursday, Jan 30, 2025

Why Activated Alumina is the Best Desiccant for Dry Air and Moisture Removal?

Read More...

- Wednesday, May 08, 2024

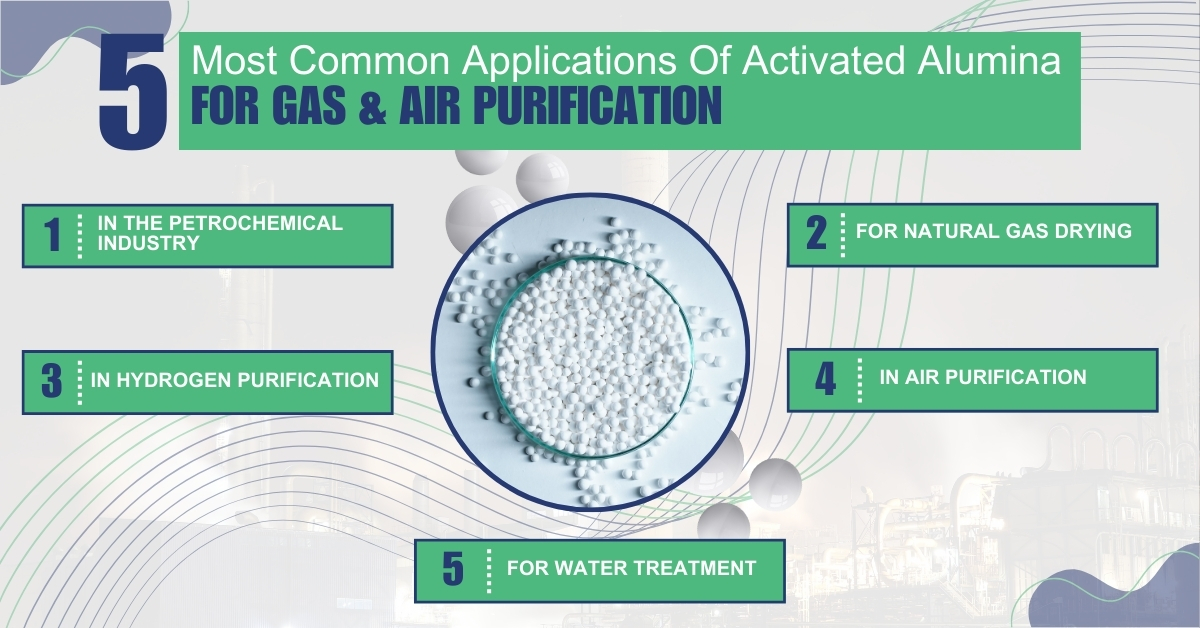

5 Most Common Applications Of Activated Alumina For Gas & Air Purification

Read More...

- Saturday, Mar 09, 2024

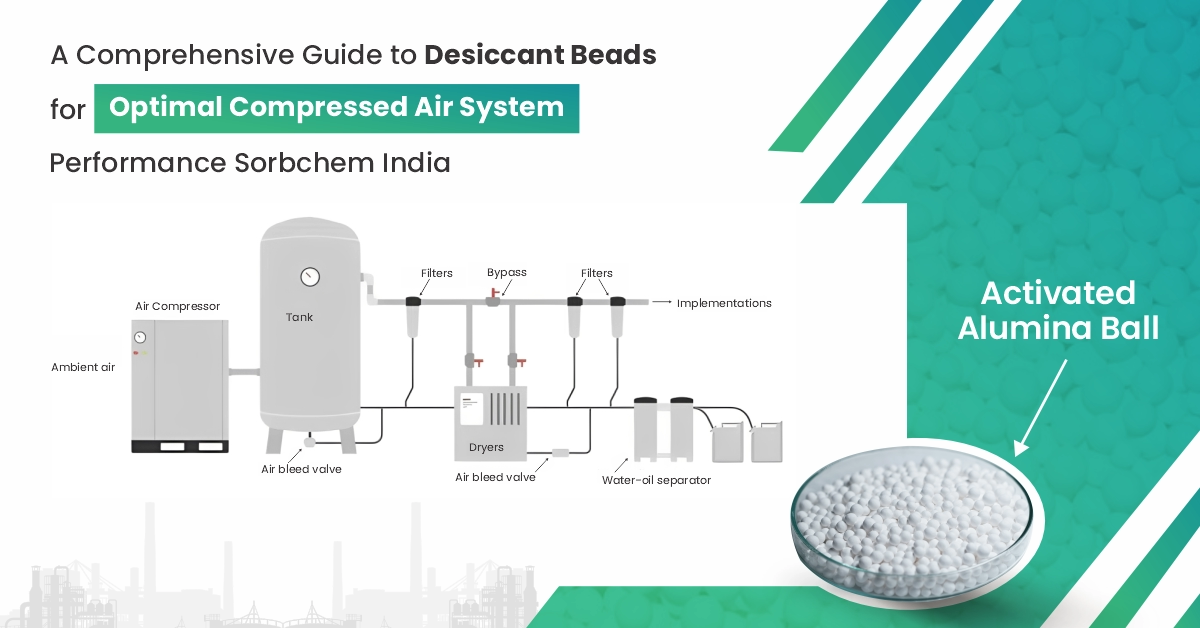

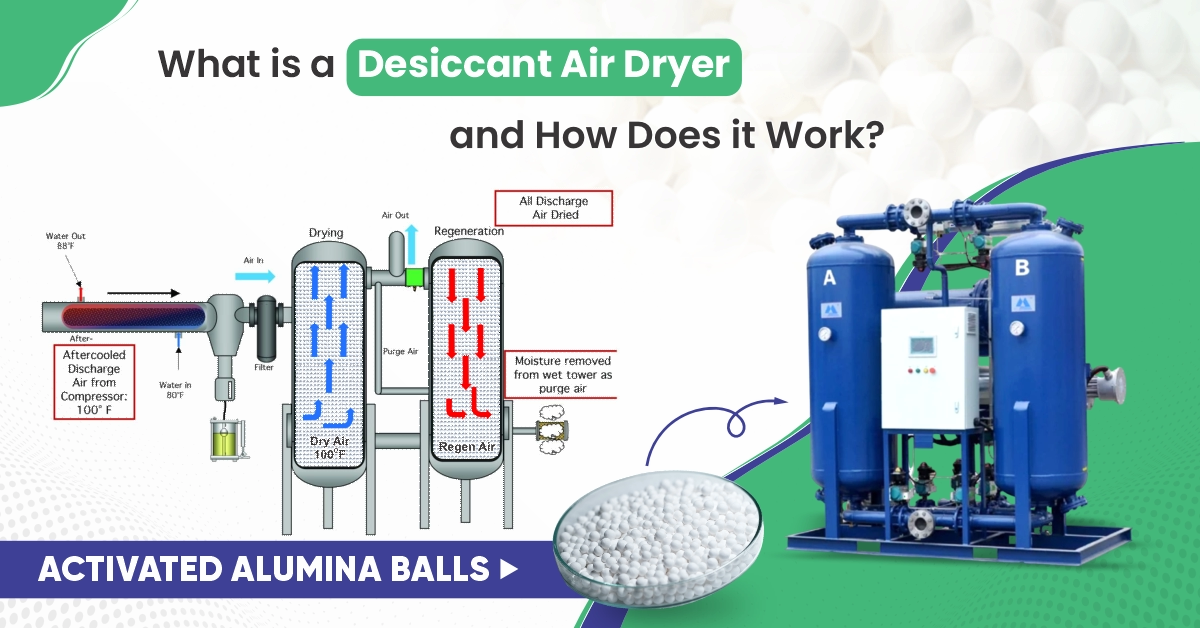

Compressed air dryer desiccant – Activated Alumina Desiccants Beads

Read More...

- Thursday, Mar 07, 2024

Choosing The Right Replacement Desiccant- Alumina Balls and Its Importance

Read More...

- Saturday, Feb 03, 2024

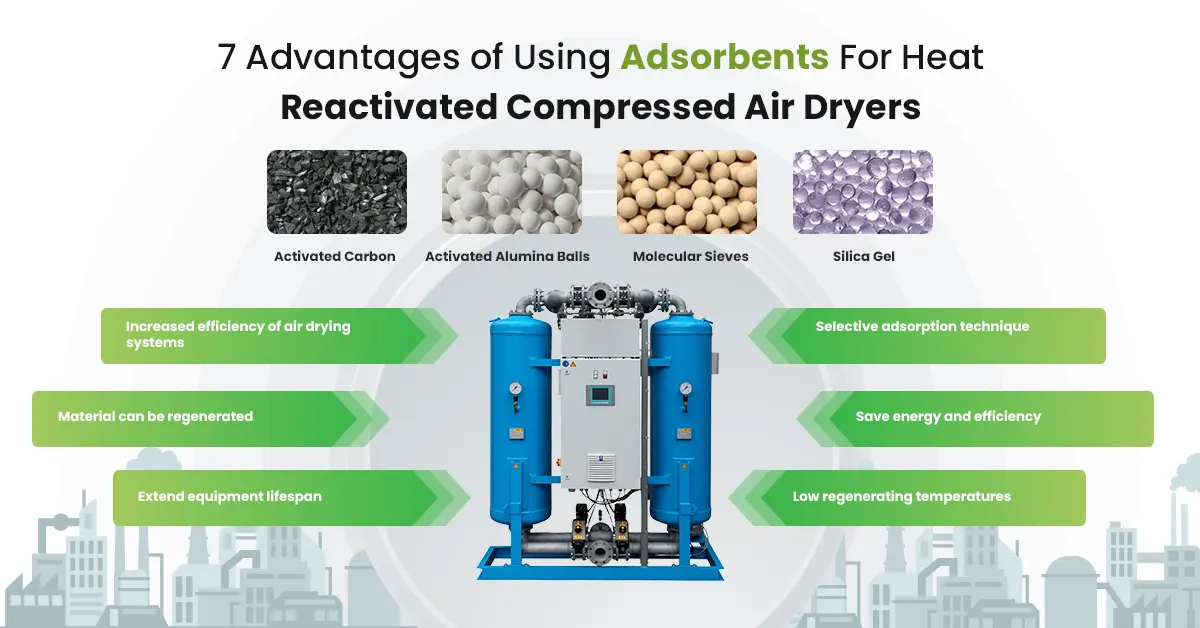

7 Advantages of Using Adsorbents For Heat Reactivated Compressed Air Dryers

Read More...

- Tuesday, Jan 30, 2024

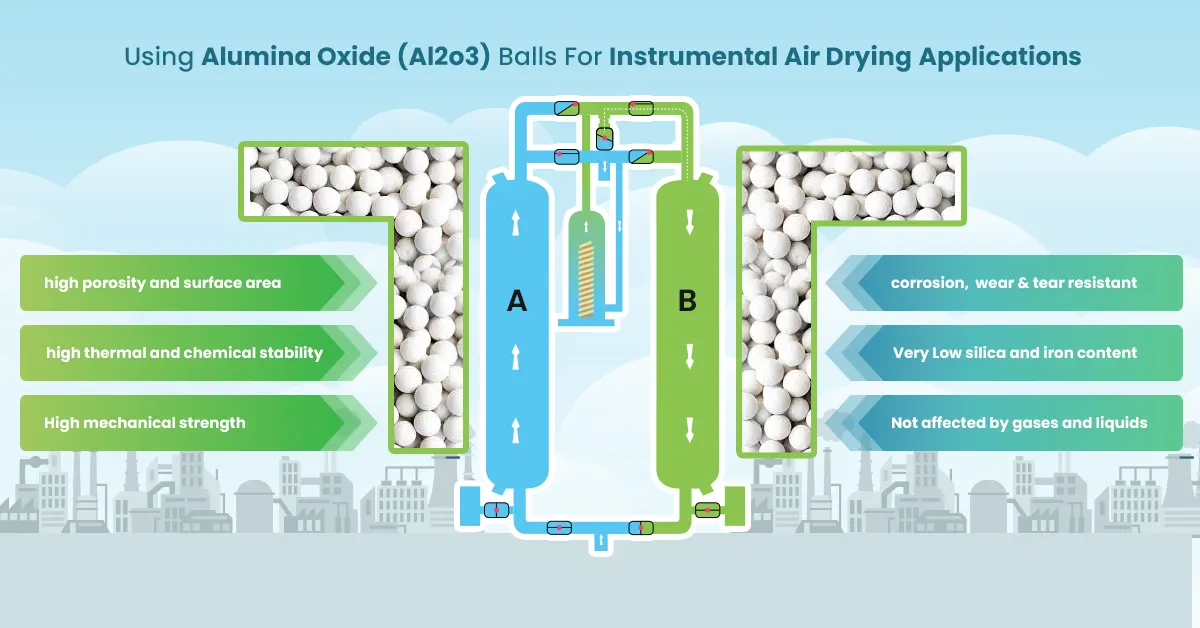

Using Alumina Oxide (Al2o3) Balls For Instrumental Air Drying Applications

Read More...

- Saturday, Dec 30, 2023

Why Should You Choose High Density Alumina Ball 12mm For Your Applications?

Read More...

- Wednesday, Sep 20, 2023

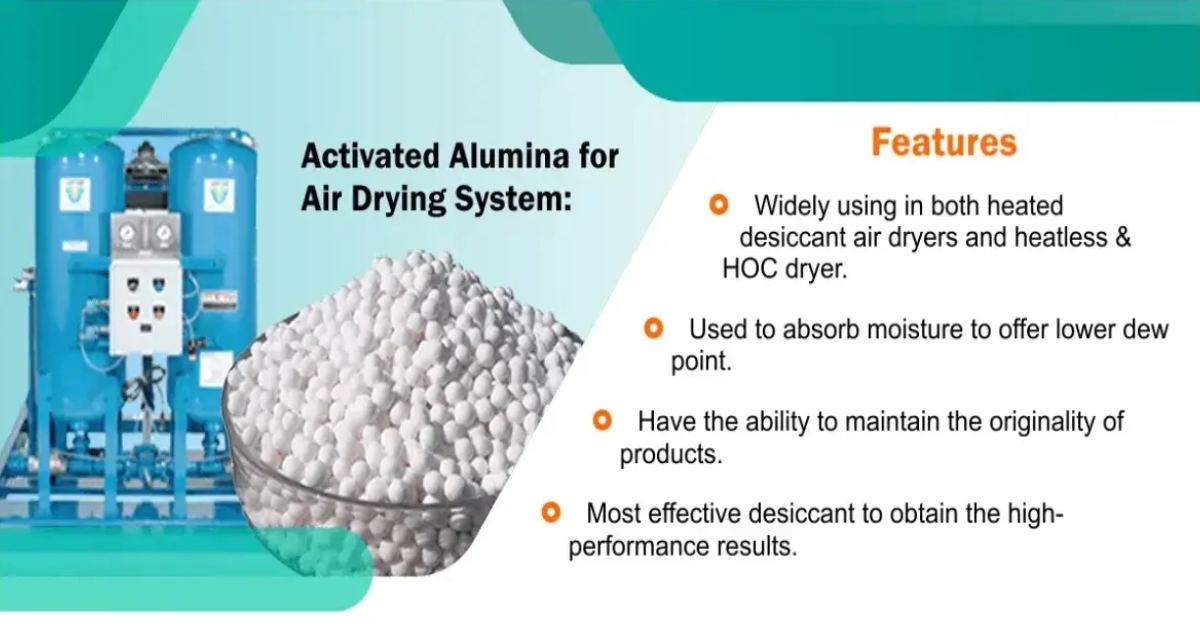

Activated Alumina For Your Air Dryer- What You Need To Know Before Using This Desiccant

Read More...

- Thursday, Mar 02, 2023

How Activated Alumina Balls Can Improve Oil Purification Process

Read More...

- Friday, Jul 15, 2022

Activated Alumina for Your Air Dryer: What You Need to Know Before Using

Read More...

- Friday, Feb 28, 2020

Best Effective Ways Of Removing Moisture Using Activated Alumina Balls

Read More...

- Tuesday, Feb 25, 2020

How Activated Alumina Deal with Moisture Problems in Transformer Oils?

Read More...

- Saturday, Dec 07, 2019

Activated Alumina Balls Are a Must For Chemical Industry to Maintain the Dryness

Read More...

- Saturday, Dec 07, 2019

Activated alumina AD101: The Multi-Utility Substance with Water Purifying Quality

Read More...

- Thursday, Dec 05, 2019

Activated alumina - An Effective and Improved Desiccant for Manufacturing Industry

Read More...

- Thursday, Dec 05, 2019

Activated alumina – a Smart and Effective Option for Industrial Air Drying

Read More...

- Thursday, Dec 05, 2019

Activated Alumina Balls - An Effective Desiccant with High Absorbing Capacity

Read More...

© 2026 Activated Alumina Balls. All rights

reserved.